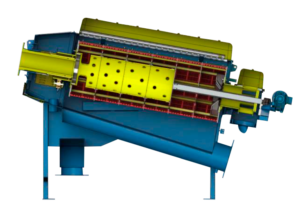

O Filtro NoBLOCK® foi desenvolvido para sanar um dos maiores problemas na operação dos separadores magnéticos do tipo WHIMS, que é o entupimento das matrizes magnéticas.

O ENTUPIMENTO DAS MATRIZES MAGNÉTICAS IMPACTA DIRETAMENTE AS USINAS DE CONCENTRAÇÃO NOS SEGUINTES ASPECTOS:

A experiência vem mostrando que a utilização de peneiras vibratórias como equipamentos de proteção não é uma técnica 100% eficiente. Eis algumas das principais vantagens da utilização do Filtro NoBLOCK® em relação às peneiras vibratórias.

| Tela | 0,6mm | 1,4mm | 3,5mm |

| Capacidade de Alimentação(*) | 80 m³/h | 250 m³/h | 300 m³/h |

(*)Referência para polpa de minério de ferro com 50% de sólidos em massa.

Pode variar em função da distribuição granulométrica

.

© Copyright 2021 – Todos os Direitos Reservados – Gaustec Magnetismo.

Dev by: Creative Dev & Design